VivoZ BioLabs, a startup company located at City College, is working towards bringing personalized treatment for cancer patients. The potential for personalized medicine can lead to better diagnosis, treatment and lower cost for patients. This is heightened in cancer patients where time is precious and administering ineffective drugs can be avoided.

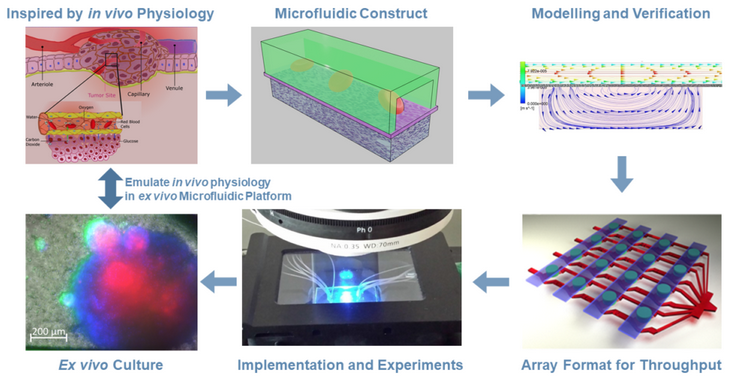

The VivoZ platform consists of microfluidic chips where tissues, cells or organoids can be cultured for several weeks in multiple arrays ready for diverse experimentation. The chips emulate in vivo physiology in an ex vivo microfluidic platform, the samples function as if they were in the body. In the future, the company hopes to provide compound screening services for pharmaceutical industry and clinical oncology with complimentary diagnostic tools for personal medicine. These developments would allow for personalized cancer treatments by targeting specific tumor attributes.

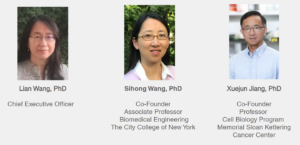

The company was founded in 2014 by Dr. Sihong Wang, Biomedical Engineering Associate Professor at City College, Dr. Zeynep Dereli-Korkut, a former postdoctoral fellow of the Wang Lab, and Dr. Xuejun Jiang from Memorial Sloan Kettering Cancer Center. The Chief Executive Officer, Dr. Lian Wang, has 15 years of Research and Development leadership experience in the pharmaceutical industry.

The paradigm followed until recently in the pharmaceutical industry was to treat a statistically prevalent disease, as it is more economical to offset the cost of drug discovery and drug development if the drug itself can be marketable to a larger share of the population. In other words, drugs were developed for more “popular” diseases rather than be customized or well-tailored to the patient themselves. – Dr. Rezwan

Two employees: Dr. Rezwanuddin Ahmed, Research Associate, and Raymond Briones, Biomedical Engineer, are Grove School of Engineering alumni who previously conducted research in Dr. Wang’s lab and joined the company partly because of their approach to aid in treating cancer.

From Dr. Rezwan perspective, a major challenge is financial. “I think that challenge we’ve run into is financial. Okay, we get initial seed funding, but then to apply for Phase II grants you need to have a business model of what market you’re selling, compared to academic, where the goal isn’t necessarily commercial.”

A second challenge to the financial challenge is mass production. As Dr. Rezwan adds that when researchers often build equipment by hand, often with sophisticated machinery, it can take hours to produce the product. The third major challenge is in selecting appropriate facilities for manufacturing as the materials need to be biocompatible.

“Before I started working in Dr. Wang’s lab, I wanted to research stem cells. In 2019, Dr. Wang and I discussed working in one of her labs and she told me about her microfluidics lab. It interested me because of her vision of having a startup company that focuses on personalized medicine and helping drug discovery. I thought that went in tandem with what I wanted to do, so I pursued working in her lab” says Raymond, who manufactures microfluidic devices for testing, refines and reviews code, develops GUI for image analysis software, analyzes image-based datasets, and performs tissue experiments along Dr. Rezwan.

Startups give you a lot of experience in the beginning compared to working in a bigger company, where you only have limited tasks and don’t really learn as much. – Raymond Briones

Employees Dr. Rezwanuddin Admed and Raymond Briones, respectively.

Dr. Ahmed, Research Associate, designs and develops the microfluidic devices, performs experiments, develops code and algorithms for image analysis. While some find the transition from working in a lab or a startup challenging, Dr. Rezwan felt that teaching undergraduate senior design courses for the Biomedical Engineering department trained him to be a leader.“ Helping students brainstorm solutions to industry problems, consider competitor’s offerings and then rely on his expertise in area such as resources available across the CCNY campus is like running a team in a company.”

City College collaborates with the company, allowing for microfluidic device fabrication at the Advanced Science Research Center (ASRC) and the Electrical Engineering Department’s Cleanroom at Steinmann Hall. Tissue experiments are conducted in Dr. Wang’s lab. The company is funded by grants from the National Science Foundation including Small Business Technology Transfer Program (STTR, $224,700) and Innovation Corps Program (I-CORPS, $50,000). In addition, the Zahn Innovation Center at City College provided $50,000 to fund the company.

Edgar Llivisupa is a journalist based in New York who joined the RICC in May 2021. Currently a Journalism and Spanish major at Baruch College he has covered business, science, culture and transit, in addition to living in Spain for two years to improve his Spanish proficiency.