The members of The Grove School of Engineering’s Combustion and Catalysis Lab actively strive to produce innovative solutions to our nation’s waste and energy problems. “In general, what we look at is combustion and catalysis processes,” says the lab’s director, Chemical Engineering Professor Marco Castaldi. “Not only do we try to understand that fundamentally — the mechanisms, the fundamental physics and chemistry associated with it, we also use those combustion and catalytic processes to use what society considers waste materials to generate energy.” The lab additionally explores energy conversion strategies that do not involve combustion, like high-temperature gasification and pyrolysis.

The waste streams of these processes often leave behind residual byproducts that are incapable of being converted. But even these byproducts can be used, explains Dr. Castaldi. “Usually the byproducts are metals and minerals; and catalysts are made up of metals and minerals as well. Classic catalysts, that you use in your automotive catalytic converter, are platinum and rhodium, or alumina. These materials are common waste-to-energy process residuals.”

“The idea of what we try to look at is not only the real fundamental academic understanding, but how can we use these processes in an environmentally benign way to make useful products or energy that society needs.”

Dr. Castaldi’s work has shown that waste-to-energy residuals can reduce NOx and sulfur dioxide emissions from combustion systems. NOx, a compound some scientists consider to be a pulmonary carcinogen, contributes 300 times more to ozone depletion than carbon dioxide and can stay in the atmosphere for over 100 years.

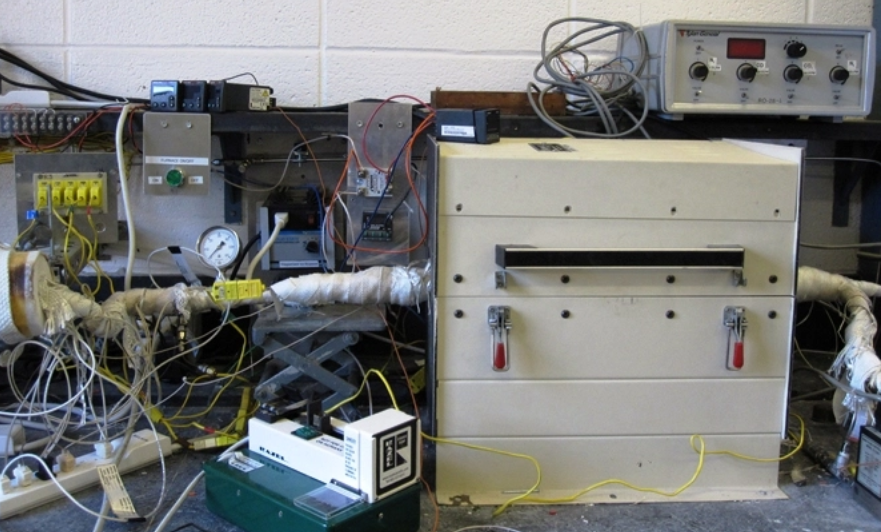

Approximately 80% of the lab’s work is experimental and the other 20% is analytical. The experimental portion involves constructing apparatuses at the bench to test chemical engineering theories, while the analytical work is more translational and involves applying the research extramurally to assess how well it solves real-world problems.

One of his lab spaces is dedicated to research done in conjunction with ConEdison. “We are looking at materials that can improve the insulation of conduits. Some of them are 50 years old, maybe more, and they have to replace them… so we’re trying to answer the question of what is the best material to replace them with?”

Manhole explosion

In a research collaboration with ConEdison, Castaldi says, “is quite dramatic. You may have seen videos, maybe on YouTube, of manholes, in New York City, that explode, and they’re trying to figure out why.” In Steinman Hall, a 6,000 pound blast chamber that can sustain the high pressures generated from combustion was recently installed. ConEdison can insert their conduits and equipment into this chamber, which is capable of replicating the real-world pressures that might cause projectile manholes. This enables ConEdison’s engineers to better think about how they can modify the manholes or what they can insert to prevent these explosions from happening. Blast chambers are instrumental in rigorously testing how effective ConEdison’s solutions are so that fewer people are injured.

In recognition of Castaldi and his collaborator’s outstanding long-term commitment to environmental harm reduction, they’ve been awarded $1.0 million in funding through the Department of Energy’s Advanced Research Projects – Energy (ARPA-E) program. The proposal for this award was drafted in a year-long team effort involving collaborators in industry and academia. Collaborators included members at the Grove School’s Department of Chemical Engineering, CUNY’s Advanced Science Research Center, North Carolina State University, and the University of Maryland. Industry partners are represented by Innoveering, SpG Consulting and Covanta.

This team, comprised of specialists of various expertise, also received funding from federal agencies such as the Department of Energy and the Department of Defense. Support from other federal agencies in combination with industry supports much of the research. They have also received funds from the American Chemistry Council, and the Environmental Research & Education Foundation (EREF). “With our partners at North Carolina State University and the University of Virginia, about 4 years ago we received the largest award that EREF ever gave out,” he says. It was a $1.2 million award disbursed over 3 years. The team also has received funding from companies like BASF and ExxonMobil. The collaboration and team-based approach provide City College students with unprecedented levels of access to professional development resources. It even acts as a vocational bridge.

“It gives students and recently graduated seniors a lot of opportunity. Our team helps them make connections, so they go on to get great jobs. Our students are now at the Office of the Mayor in Sustainability, and others are at Covanta, Exxon Mobil, and BASF.

Opening ceremony of Reppie Waste to Energy plant Koshe- Addis Ababa, Ethiopia. (Minasse Wondimu Hailu – Anadolu Agency)

Dr. Castaldi’s work is also impactful globally. A few years ago, Dr. Castaldi was featured on President Boudreau’s radio show, “CCNY to the World.” He credits this show for helping to raise the work of the team in the international arena resulting in visits by delegations from China, Bulgaria, the European Union, and South America, “One delegation [from] Addis Ababa, Ethiopia, [visited] probably 7 to 8 years ago, to learn about waste-to-energy; and Ethiopia built a waste-to-energy facility about 2 and a half years ago!”